Static Tensile Test of Non-Woven Cloth Selection of the Best Fitted Grips for Autograph (V)

Non-woven cloth, or cloth not woven from yarn but made from self-knit, mechanically and chemically processed fiber sheets, is now widely used in a market that supports a production of 200,000 tons a year.

Its demand is expected to increase, particularly in those fields using fine and absorptive ecological materials (see Table 1).

Related industries are interested in tests evaluating the appropriate thickness and strength of the cloth fitted to respective use.

The following are several test examples using the Shimadzu Autograph in various evaluations of strength.

Specimen

|

Name |

: |

Non-woven cloth |

|

Shape |

: |

Long rectangular, width 50mm, thickness 1mm, length 200mm |

Testing conditions

|

Testing machine |

: |

Shimadzu Autograph |

|

Capacity of load cell |

: |

5kN |

|

Testing speed |

: |

100mm/min. |

|

Distance between grips |

: |

100mm |

|

Room condition |

: |

Temperature 25゚C, humidity 50% |

Best fitted grips

|

Type |

: |

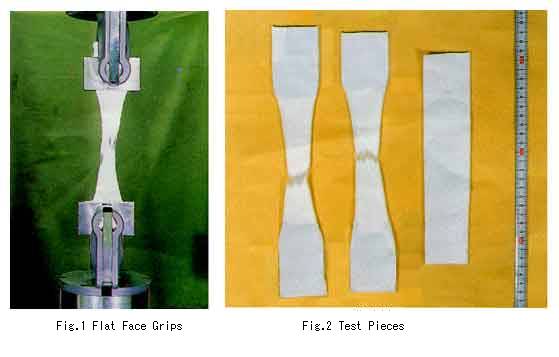

Pneumatic flat grips, with a footvalve |

|

Grip face |

: |

flat type, rubber coated |

|

Capacity |

: |

5kN |

|

Pneumatic pressure |

: |

400kpa(4kgf/cm2) |

Mounting of specimen onto grips

Insert a test piece into upper and lower grips and press the footvalve, fastening the specimen by a stroke of the air cylinder.

Safe operation is secured by the speed controller.

Test results

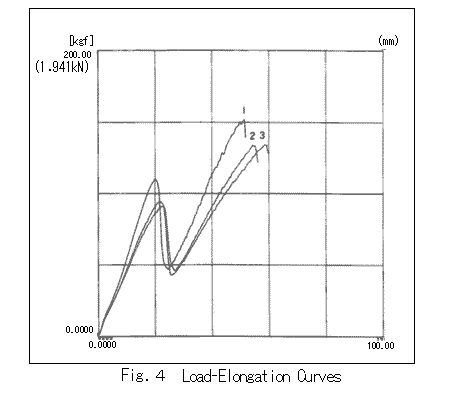

Fig.3 shows the test results in the form ofa load-elongation curve, and Fig.4 presents overlapped curves of three tests to show the reproducibility of the characteristic behavior.

The first peak is a point where the width of the test piece rapidly narrows just beyond its elastic limit. The second peak is the point of maximum load, where the width of the test piece narrows around the center and it is ideally broken at the center, as shown in Fig.2 (photograph).

This test assures that a reliable cloth test can be performed with pneumatic-type flat face grips. The characteristic curve obtained in this test shows special behavior typical to non-woven cloth, but never seen in others.

Table 1 Use of Non-Woven Cloth

| Everyday usage | wet towels, paper diapers, cooking paper, sanitary goods |

| Industrial usage | filters, heat insulators, cars, battery separator materials, IC circuit substrates |

| Clothing usage | lining cloth, apparel |

| Agricultural usage | hydroponic culturing materials, gardening materials, root penetration prevention materials, irrigation materials |

| Architectural usage | carpets, wall materials, ceiling materials |

| Civil construction projects usage | road construction, reclamation work, shore protection, embankments, forest maintenance, park construction |

| Medical care usage | masks, operation cloths, bed sheets |

Table Data on Test Piece

| Test result | ||||

| No. | Max. load | Elongation atmax. load | ||

| kN | kgf | (mm) | (%) | |

| 1 | 1.48 | 151.6 | 51.0 | 51.0 |

| 2 | 1.30 | 133.5 | 54.6 | 54.6 |

| 3 | 1.31 | 133.9 | 58.8 | 58.8 |