Supporting Innovation in PAT

The ongoing optimization of production processes in the chemical and pharmaceutical industries is placing new demands on on-site monitoring and analysis. In order to be able to intervene quickly in the process, the transmission of specific measured values to the process control is crucial.

In addition to recording individual parameters, physical quantities such as temperature, pressure or density, chemical parameters such as the total content of organic carbon or nitrogen play a role, as do the contents of starting materials and reaction products of chemical syntheses. Instrumental analysis, usually performed in a laboratory, is increasingly being integrated into the process by taking samples directly from the reactor and analyzing them.

Since the reaction mixture contains starting materials, reaction products and sometimes a large number of auxiliary materials, separation processes are necessary to determine the total amount of a substance or the ratio of individual components to each other. A particular challenge in these cases is that on-site analysis has different requirements in terms of robustness, stability and rapid deployment and requires compromises in order to be used 24/7 by production personnel.

Ensuring 'First Time Right' with Shimadzu TOC-1000e

Achieve unparalleled accuracy and reliability in your ultra-pure water monitoring and CIP cleaning validation with the Shimadzu TOC-1000e (eTOC). Our state-of-the-art TOC technology provides rapid and continuous online analysis, ensuring immediate detection and correction. Featuring a powerful UV excimer lamp and a one-year tool-free maintenance and recalibration interval, the TOC-1000e guarantees minimal downtime and maximum efficiency. Depend on the TOC-1000e to deliver precise, real-time data that supports your commitment to quality and compliance.

Streamlining production cycles with Nexera FV

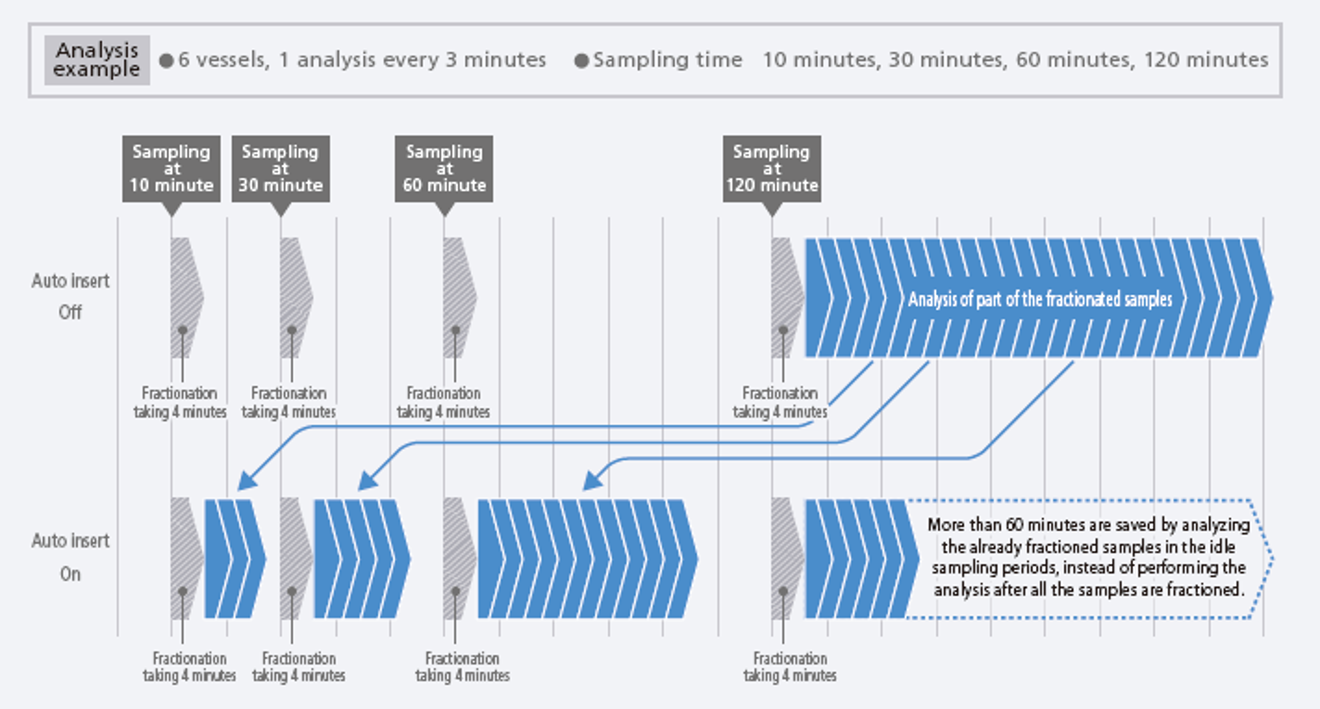

The Nexera FV and LabSolutions™ FV form an advanced UHPLC system designed to monitor flow and batch synthesis reactions and automate formulation dissolution testing. Meeting FDA and ICH standards, this system supports a Quality by Design (QbD) approach using process analytical technology (PAT). It automates critical quality attribute (CQA) measurements, reducing labor and human error while ensuring high data reliability. The Nexera FV's unique flow-through vial autosampler handles periodic sample collection for optimal analysis timing. It also functions as a general-purpose UHPLC system, enhancing operational efficiency. LabSolutions FV simplifies online analysis settings, making it ideal for process monitoring and dissolution testing.

Enabling a higher degree of automation and control with LabSolutions

LabSolutions, the analytical software platform from Shimadzu, combines the control of various instruments and techniques, including chromatography, mass spectrometry, spectroscopy, and instruments for determining total organic carbon and nitrogen, as well as testing machines. Add-on programs, such as LabSolutions FV, serve as the user interface on the operator's side, while user access, methods, and data are managed and stored according to compliance criteria. Reporting test results is essential and can be tailored to individual requirements. The Multi Data Report function in LabSolutions CS allows for the combination of results from different instruments into a single report and facilitates calculations based on measured results, enhancing statistical analysis and overall data management.

Explore Shimadzu's Process Analytical Technology solutions

Shimadzu offers a broad range of other high-quality products for comprehensive PAT. Our innovative solutions are designed to ensure precise and reliable results across various applications. Explore our portfolio to find the perfect fit for your analytical requirements.

-

Highly-advanced Online TOC analzser, used in a wide range of water analysis applications.

-

State-of-the-art technology in the smallest casing – Online TOC analyzer for pure water applications.

-

Automates Online LC Analysis, from Sample Collection to Data Collection

-

LabSolutions CS features an innovative operating environment and provides complete data management to ensure secure information in networked laboratories.

-

LabSolutions DB has a data management function and is compliant with the ER/ES Regulations. It is optimally configured for customers using a PC.