SPG-V500

INDUSTRY

KEYWORD

INTRODUCTION SERVICE&PRODUCTS

SPG-V500

In the production of external cavity lasers (ECL), precise adjustments to the optical elements are required to ensure stable oscillation at the single desired wavelength.

The task of optical adjustment requires repeated fine adjustments to the elements and wavelength inspections (scans), so the time needed becomes an issue.

Note: What is an External Cavity Laser (ECL)?

An ECL is a type of laser in which only a specific wavelength (mode) is selected using a diffraction grating, and is fed back to a semiconductor laser, producing a single wavelength (single mode oscillation).

*Affiliates and titles of the interviewee are current as of the time of reporting.

Learn more below.

The SPG-V500 can obtain spectra simultaneously using an array sensor, enabling the continuous monitoring of instantaneous spectral changes.

Since the spectrum can be checked in real-time while performing optical adjustments, it plays a role in streamlining the adjustment process.

The instrument has a function enabling the overlay of a spectrum on the graph of a rated standard, which can be used as a reference for wavelength adjustments.

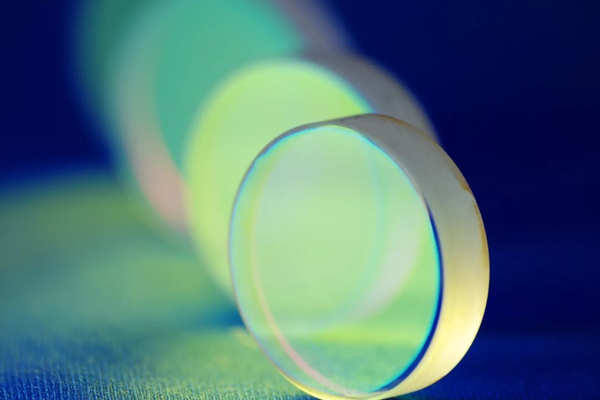

With the SPG-V500, thanks to dia. 600 µm multimode fiber incidence and spatial incidence, high-wavelength resolution of approximately 0.02 nm (Typ.) is obtained.

Unlike instruments requiring single mode fiber incidence, fine optical adjustments are no longer required, which simplifies high-resolution measurements.

Fine adjustments to optical elements can now be performed continuously while observing the wavelength.

In addition, the high-resolution measurements no longer require alignment of the measured light to single mode fibers.

As a result, the time taken for assembly adjustments can be substantially reduced.

It is astonishing that optical adjustment tasks, which until now naturally involved operating the mechanism, stopping it, and checking it, can now be performed smoothly without stops. Further, it took time for alignment with single mode fibers so as to obtain wavelength resolution capable of separation in longitudinal mode, but this is no longer necessary, which contributes to substantially speeding up the process.