Convincing Cost Performance

Precision Universal Testing Machines

.jpg)

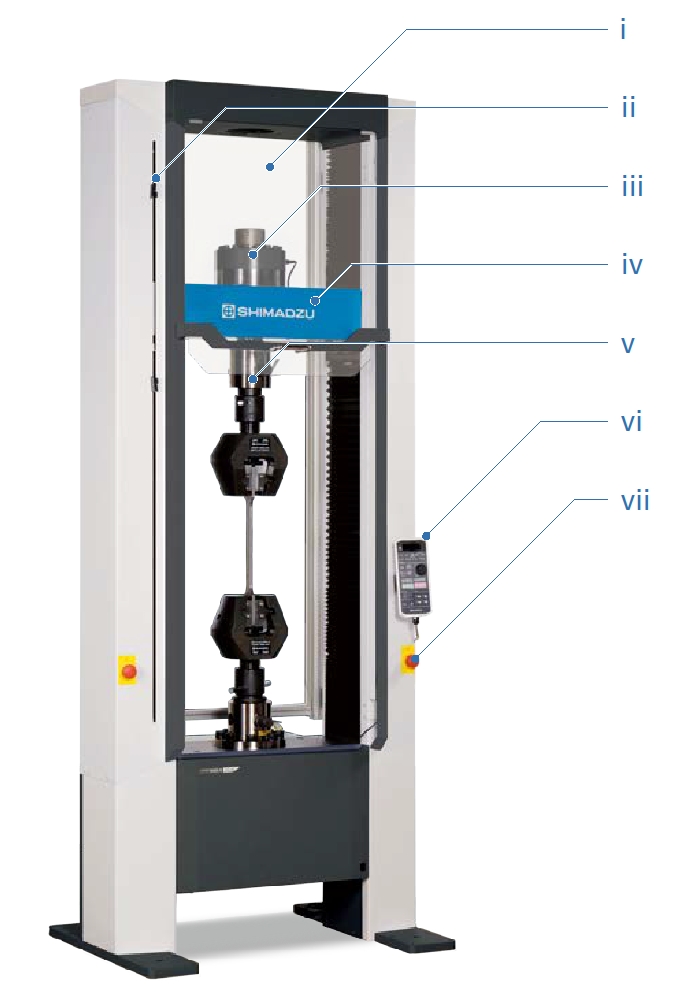

The Shimadzu AUTOGRAPH AGS-X2 series provides superior performance and practical testing solutions for a wide array of applications. Offering high-level control and intuitive operation, the AGS-X2 series sets a new standard for strength evaluations while providing the utmost in safety considerations in a modern, stylish design.

The AGS-X2 comes standard with industry-leading TRAPEZIUM X-V data processing software. Offering comprehensive functions, TRAPEZIUM X-V offers an unparalleled level of operation. TRAPEZIUM LITE X, Shimadzu’s entry-level data processing software, provides enhanced productivity and efficiency for quality control operations.

AGS-X2 Provides Practical, Affordable Testing Solutions

Offers real-time auto tuning of control parameters, based on measured test force and strain data. Safely make comparisons to unknown sample data without the need for preliminary tests.

In addition, the AUTOTUNING FUNCTION easily performs strain control, an ISO6892 requirement.

|

IRON & STEEL | In addition to conventional stress control, tensile testing with strain control is increasingly in demand. ISO 6892 JIS Z2241 |

|

PLASTICS & RESIN | Measuring the modulus of elasticity in the ultra-small strain domains proscribed by ISO and JIS standards has become a necessity. ISO 527 ISO 178 JIS K7171 |

|

CERAMICS | Many samples are damaged by microscopic displacements, so accurate control is needed, right from the start of testing. |

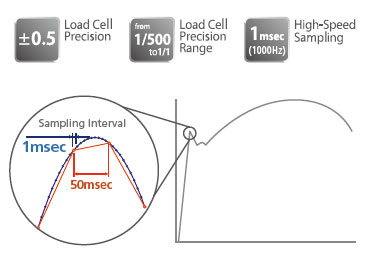

The wide, guaranteed load cell precision range of 1/500 to 1/1 improves testing efficiency and ensures that virtually all of your testing can be performed without switching the load cell or jig. Furthermore, high-speed sampling of 1 msec ensures no missed strength changes.

The safety function stops the testing machine if force changes exceed a certain level during specimen setting or return.

In addition, setting stroke limiters is easy with one touch of the switch.

Controls scattering of the test specimen during testing. The interlock improves safety: operators can open and close it easily with the slide mechanism.

Features emergency-stop switches on both sides (20 kN–300 kN frame).

New and enhanced functions support easier, more efficient testing

A vertically sliding safety guard is available. Opens easily with one hand. When the protection cover is open, an interlock function disables testing and return movement.

Pinch and slide; release to lock. One-touch stroke limiters permit simple one-touch adjustment and firm locking of the crosshead stroke limit positions.

For the range of 1/500 to 1/1 of the load cell rating, a single load cell that guarantees test force accuracy to ±0.5% of the indicated value (for high-precision type) covers an extensive testing range. The load cell rated value is stored in the calibration cable and automatically recognized when the cable is connected.

Achieves a 2,000 mm/min testing speed and a 2,200 mm/min return speed (20 kN frame), significantly reducing the time required to conduct repetitive testing.

Adopts a single joint for both tension and compression tests. This makes it easier to exchange jigs. In addition, the joint is set with a nut placed in the upper part of the loading cell, which allows for safe detachment of the joint on the table.

The main operation panel enables the development and storing of test conditions, allowing testing without having to connect to a PC. Perform various operations with the jog wheel, such as opening and shutting the button for the automatic extensometer. The main operational panel is movable, allowing convenient adjustment of the angle. The display language can be selected as English or Chinese.

* The controller is needed separately for the automatic opening and shutting of jigs.

Reliably cuts off power to the servo amplifier, instantaneously stopping crosshead movement in the event of an emergency.