AUTOGRAPH AGS-X2 Series - Specs

Precision Universal Testing Machines

| Model | AGS-20kNX2D | AGS-50kNX2D | AGS-100kNX2 | AGS-300kNX2 | ||

|---|---|---|---|---|---|---|

|

|

|

|

|||

| Table-top Type | Floor Type | |||||

| Force Measurement |

Accuracy | High-Precision Type (1/500, ±0.5%) |

Within ±0.5% indicated test force (at 1/500 to 1/1 load cell rating) | Within ±0.5% indicated test force (at 1/250 to 1/1 load cell rating) | ||

| Conforms to EN 10002-2 Grade 0.5, ISO 7500-1 Class 0.5, BS 1610 Class 0.5, ASTM E4, and JIS B7721 Class 0.5.*1 | ||||||

| Standard-Precision Type (1/500, ±1%) |

Within ±1% indicated test force (at 1/500 to 1/1 load cell rating) | |||||

| Conforms to EN 10002-2 Grade 1, ISO 7500-1 Class 1, BS 1610 Class 1, ASTM E4, and JIS B7721 Class 1.*1 | ||||||

| Calibration | Automatic test force calibration: select tensile, compression, or tensile and compression | |||||

| Crosshead | Speed Range | 0.001 to 2000 mm/min (stepless) | 0.0001 to 1000 mm/min (stepless) | 0.0001 to 500 mm/min (stepless) | ||

| Max. Return Speed | 2200 mm/min | 1100 mm/min | 550 mm/min | |||

| Crosshead Speed Accuracy*2 | ±0.1% | |||||

| Crosshead Speed and Permitted Test Force | To load cell capacity across entire speed range | Under 200 kN: 0.0001–500 mm/min (entire speed range) 200–300 kN: 0.0001–400 mm/min |

||||

| Crosshead – Table Distance (Tensile stroke) *3 | 1250 mm (765 mm, MWG) | 1210 mm (745 mm, MWG) | 1255 mm (745 mm, MWG) | 1475 mm (635 mm, MWG) | ||

| Effective Test Width | 425 mm | 600 mm | ||||

| Crosshead Position Detection | Measurement Method | Optical encoder | ||||

| Display Method | Digital display (display resolution: 0.001 mm) | |||||

| Positional Accuracy | ±0.1% indicated value or ±0.01 mm, whichever is larger | |||||

| Data Capture Rate | 1000 Hz max.*4 | |||||

| Test Method Files | 50 files (PC link: 20 files, standalone controller: 30 files) | |||||

| Standard Functions |

|

|||||

| Accessories | Load Cell (with CAL cable), Power cable (5 m), turning rod, cable clamps, instruction manual | |||||

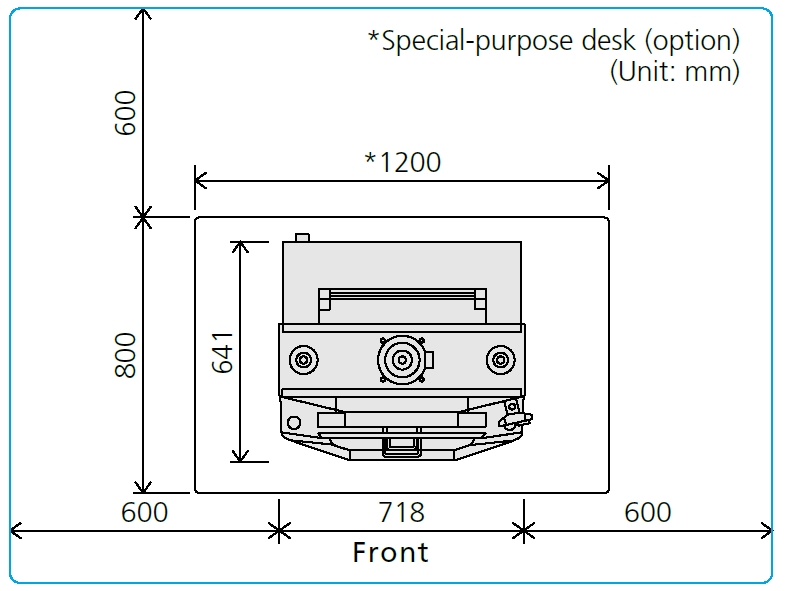

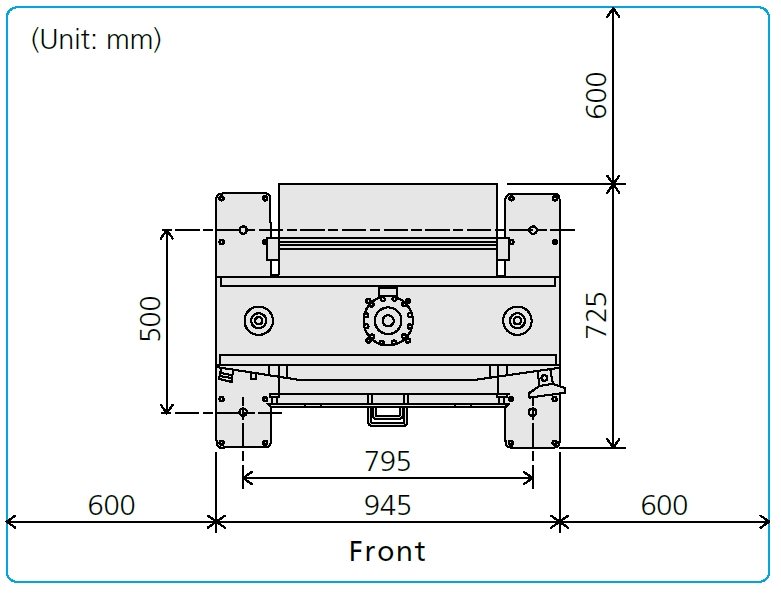

| Dimensions |  |

|

||||

| W718 × D641 × H1633 mm | W945 × D725 × H2164 mm | W945 × D725 × H2414 mm | ||||

| Weight | 235 kg | 260 kg | 525 kg | 675 kg | ||

| Power Requirements | Single phase AC 200–230 50/60 Hz 4.0 kVA | 400 V model: Three phases AC 380–440 V 50/60 Hz 4.5 kVA 200 V model: Three phases AC 200–230 V 50/60 Hz 6.5 kVA |

400 V model: Three phases AC 380–440 V 50/60 Hz 5.5 kVA 200 V model: Three phases AC 200–230 V 50/60 Hz 7.5 kVA |

|||

| Supply voltage fluctuations within ±10% of the set value. D-class (100 Ω max.) grounding resistance. |

Supply voltage fluctuations within ±10% of the set value. 400 V model: C-class (10 Ω max.) grounding resistance. 200 V model: D-class (100 Ω max.) grounding resistance. |

|||||

| Operating Environment | Temperature: 5 °C to 40 °C; Humidity: 20% to 80% (no condensation) Floor vibrations: frequency 10 Hz max., amplitude 5 μm max. |

|||||

- Offi cial certi cation after installation is recommended to comply with EN 10002-2, ISO 7500-1, ASTM E4 standards, and JIS B7721.

- Crosshead speed accuracy is calculated from the crosshead travel within a prescribed time at a constant speed between 0.5 mm/minute and 500 mm/minute.

- The tensile stroke is the effective stroke when SCG (screw-type flat grips) or MWG (non-shift wedge-type grips) are mounted.

- TRAPEZIUM X-V or TRAPEZIUM LITE X is needed for these functions. Moreover, when automatic test force/stress control (auto tuning) and the automatic strain

control (auto tuning) are used, the sampling speed becomes 10 msec. - Dataletty (option) and TRAPEZIUM X-V / TRAPEZIUM LITE X can not be used together.